Bilsing Automation offers lighter, stiffer and more harmonically stable tools made from high modulus, graphite carbon fiber.

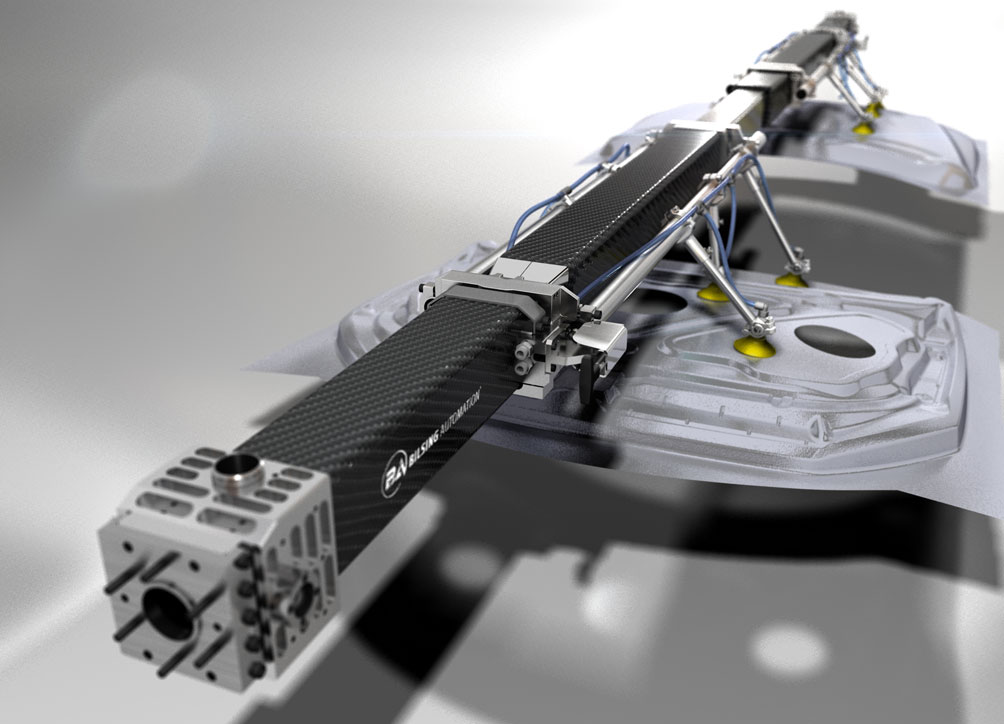

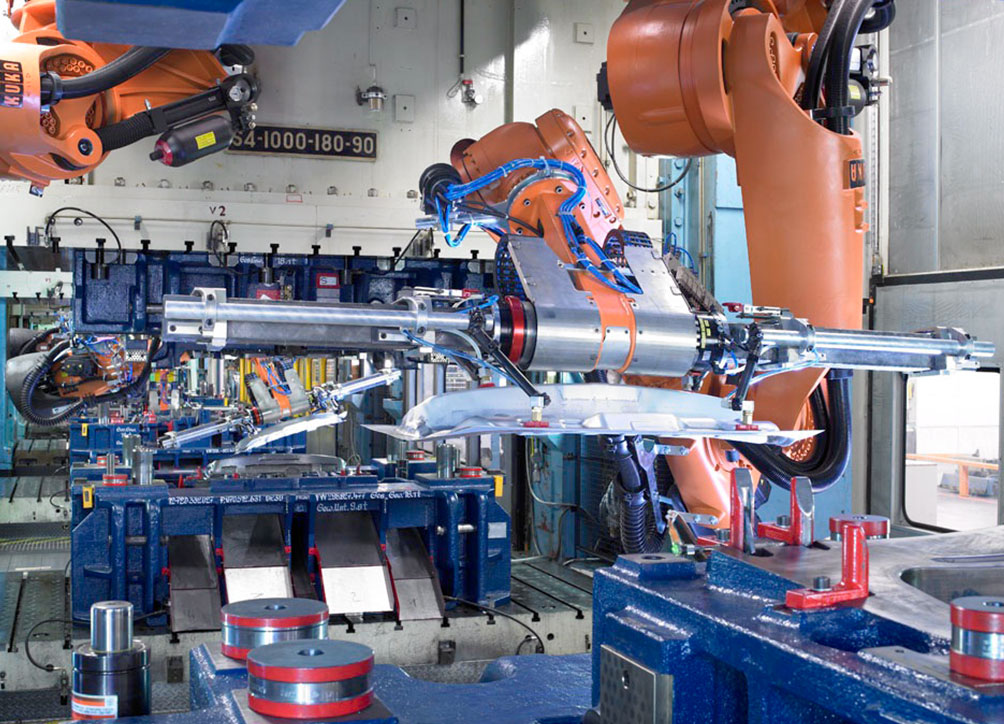

Bilsing has invested significant time and research into the development of lighter, stiffer and more harmonically stable tools made from high modulus, graphite Carbon Fiber(Cf). Our Cf solutions deliver increased strength and rigidity without being brittle – yet weigh less than half of traditional materials. Potential composite tooling applications include crossbar beams, loading and unloading beams, destacking beams, panel loading t-booms, and tooling supports for the body shop pressroom – including hot forming, injection molding, assembly and more.

The material properties of Cf reduce vibration and deflection so that tools settle more rapidly and with higher precision, allowing users to make productivity gains of up to 20%. Over its lifespan, carbon fiber tooling can provide a higher ROI when considering that users will get more parts out the door, reduce energy costs due to moving less tooling mass, and extend equipment life since the lighter mass of carbon fiber puts less stress on automation, robots, presses, etc.

Bilsing produces a series of round, square and conical composite tools as well as custom profiles for specific customer needs, which can be powder-coated to any color. Additionally, special dampening layers are added to many of the Bilsing applications making the tooling even faster and more precise.

In independent laboratory tests comparing steel, aluminum, and carbon fiber at 1,000,000 cycles with approximately 350 lb. force of tension and compression loaded, Bilsing carbon fiber beams proved to be lighter and more robust than aluminum, yet stronger than steel beams of the same size.

An added benefit of the Bilsing’s carbon fiber tooling is its modular design, which enables users to simply change out components instead of having to replace the entire unit should a component break or need to be changed out.

Higher productivity means more parts out the door, which means more money for users. The annual productivity payback achieved by composite tooling over its lifespan includes:

Composite materials are safe to use as well as recyclable. Unlike steels and some aluminums, epoxy composites do not corrode and are impervious to fluids as long as any cut sides are sealed. Bilsing’s composite tooling, manufactured with temperature-resistant glue, can operate in a wide range of temperatures, from -40°C (-104°F) to 700°C (1232°F), making these carbon fiber beams well-suited for hot forming operations.

In terms of environmental impact, unwanted composite is chopped and the matrix burned off to recover energy trapped in the chemistry. Short fibers are used for reinforcement in injection molding or concrete while other recycling processes can convert the material back to its basic elements.

MODULAR

Bilsing’s carbon fiber tooling typically features a modular design with extreme design flexibility, enabling users to simply change out components instead of having to replace the entire unit should a component break or need to be changed out.

STRONG

Bilsing’s fastening methodology marries the carbon fiber structure at the joints first with an adhesive and then reinforces it with steel bolts through the core. This Bilsing-developed technology results in a joint that is as strong as a steel weld while lowering manufacturing costs.

FLEXIBLE

Bilsing’s carbon fiber profiles are compatible with a wide variety of popular brand standard vacuum, gripper and power clamp components, making it easy for companies to switch to a CF solution.

Click on an image to view full size.